Soldering Assembly

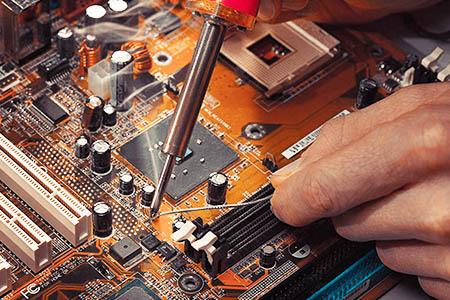

Soldering Assembly Technologies and Processes

Due to many component sizes, special components and components that cannot be machinable, we use piston soldering methods for assembly. In this case, the production and connection for hybrid is carried out with LP (by means of selective/piston soldering). For example, we carry out combined assembly / surface fastening of SIL lead frames and DIL lead frames with 1.27 mm to 2.54 mm pitch.

What can C-Alley Soldering Assembly offer?

Welding is a common method of attaching electronic components to a circuit board and establishing electrical connections.

C-Alley is a company specializing in soldering assembly and offering a variety of welding(soldering) services. Such as Surface Mount technology (SMT) welding and Through-Hole welding. Especially SMT welding is a technique that welds components directly to the surface of the board, while THT Soldering Assembly is done by inserting the component pins into the board holes and welding.

Broadly speaking, C-Alley can provide the following services:

- Component welding

- Welding process Consulting

- Quality control

- welding solutions customization

- Piston soldering process for many component sizes, special components and components that cannot be set by machine

- Preparation of hybrids and their combination with LP (by selective soldering)

- Comb mounting / Surface mounting of SIL leadframes and DIL leadframes with 1.27 mm to 2.54 mm pitch / Leadframes for SIL (Single-In-Line) / DIL (Dual-In-Line) with pitches 1.27 mm and 2.54 mm

- Dip soldering for lead-containing and lead-free joints

- Crimping and assembly of cable connections

- Gold plating and pre-tinning of components

- Surface treatment with pyrolysis process

- Production and processing of various types of adhesives (silicone-containing and free adhesives, etc.)

- Realisation of bubble-free adhesive bonding

Qualifications and certifications of our production

Our own IPC trainers permanently train our employees, and all manual soldering processes relys on IPC – A – 610. In other words, the classification and visual inspection of LP are compliance to IPC – A – 610 for the respective product classes.

- Production according to ESA standards (AeroSpace), compliance with ECSS-Q-ST-70-08, ECSS-Q-ST-70-38, ECSS-Q-ST-10-09, ECSS-Q-ST-70-26 and ECSS-Q-ST-70-30

- THT (through-hole technology) push-through mounting

- Certified personnel according to J-STD-001 (hand soldering and visual inspection according to J-STD-001), HL 3 (production of highly reliable hand soldering processes according to ESA specification), HL 4 (inspector according to ESA specification), HL 5 (repair of assemblies according to ESA specification), SMT 4 (production of highly reliable solder joints in SMT according to ESA specification), LFV (crimping, wire wrap according to ESA specification)