Metal Substrate PCB

There are many names for these products; Aluminum clad, Aluminum base, Metal clad printed Circuit Board (MCPCB), Insulated Metal Substrate (IMS or IMPCB), Thermally conductive PCBs, Metal core PCB, etc… but they all mean the same thing and perform the same way.

Metal Substrate PCBs, also known as Metal Core PCBs or MCPCBs, are specialized circuit boards designed to provide efficient heat dissipation in electronic devices. Unlike traditional PCBs that use a non-conductive substrate, Metal Substrate PCBs have a metal base layer that acts as both a mechanical support and a heat sink for the components mounted on the board.

Metal Substrate PCB are thermal management circuit boards which use a base metal material as the heat dissipated part of the PCB. They are used in high heat generating application like LED lighting in the area of high power LED lighting, Automotive Interior, Exterior Lighting, Parking Garage Lighting, LED spot light etc. The metal core can be aluminum (aluminum core PCB) and copper (copper core PCB). The most common used aluminum core PCB is the thermal conductivity at 1W/MK and 2W/MK.

The construction of a Metal Substrate PCB involves several layers: Metal Base Layer,Dielectric Layer,Circuit Layer.

Widely Used in Various Industries/Fields

Metal Substrate PCB are widely supplied in various industries, particularly in high-power and high-heat electronic devices. Some common applications include:LED Lighting, Power Electronics,Automotive Electronic

In conclusion, Metal Substrate PCBs play a vital role in thermal management for electronic devices, ensuring optimal performance and reliability. Their unique design with a metal base layer provides efficient heat dissipation, making them suitable for various high-power and high-heat applications across industries.

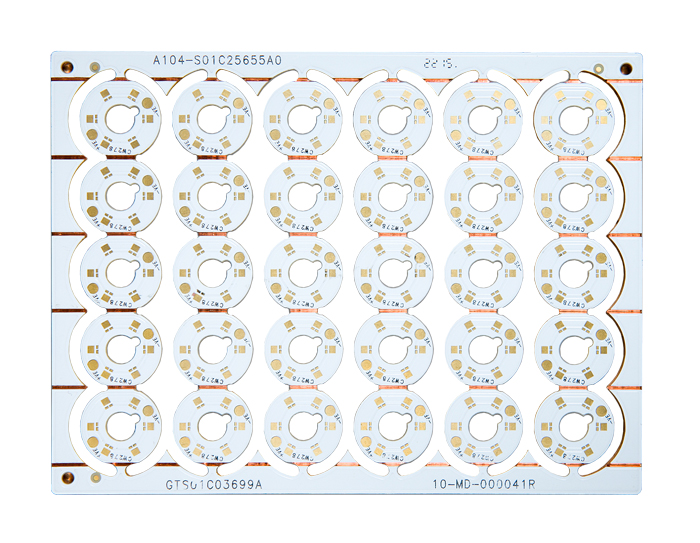

Layers:2L

Thickness: 1.6mm

Min Hole Size: 0.2mm

Min Line Width: 0.1mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance:+/-0.05mm

Notes: Aluminum base LED light PCB

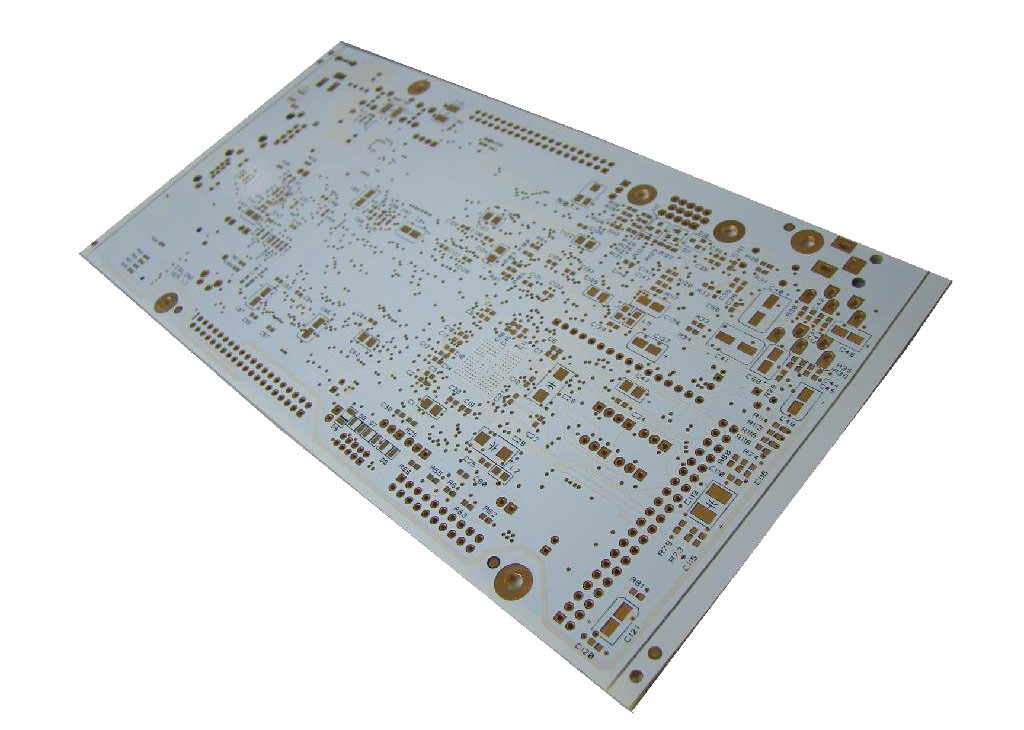

Layers: 1L

Thickness: 1.6mm

Min Hole Size: 0.2mm

Min Line Width: 0.1mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance: +/-0.05mm

Notes: Aluminum base PCB

Metal Substrate PCB Production Capability

| Item | Standard | Advanced |

| Layer Count | 1-6L | 1-6L |

| Max.PanelSize | 2L:250mm×540mm | 2L:250mm×540mm |

| Min.Finished Board Thickness | 2L:0.15mm | 2L:0.15mm |

| Min.Trace Width | 0.076mm | 0.076mm |

| Min. Drill Size | 0.2mm | 0.2mm |

| Min. Laser Drill Size | 0.075mm | 0.075mm |

| Min.Cu Thickness | 12um | 12um |

| Molding Tolerance | +/-0.05mm | +/-0.05mm |