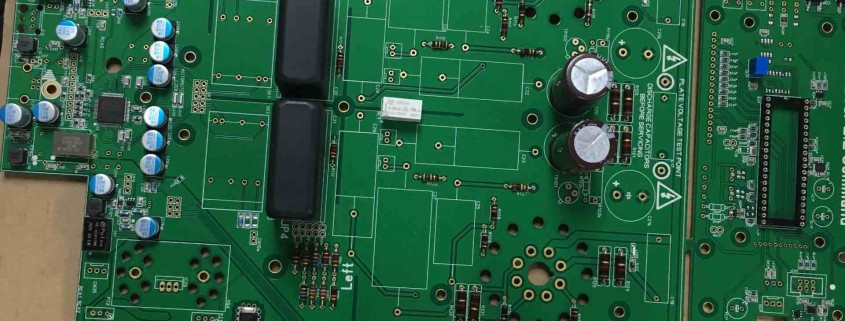

0.3mm Pitch BGA Assembly

0.3mm Pitch BGA Assembly.

As recently our client sent us a quote that need 0.3mm pitch BGA based on below specification:

1) FR4 material ? FR4

2) Board thickness ? 0.60mm

3) Board finishing ? Hot air leveling

4) Copper thickness ?1oz inner and outter. This is a 4 layer board

5) soldermask color ?Green solder mask

6) Silkscreen color ? White

7) Impedance control trace ? No impedance control

As a OEM PCBA manufacturer in China with over 10 years experience, it’s no problem to produce 0.3mm pitch BGA boards, but it’s still complex.

Standard requirements is between 0.15~0.25mm pitch.

We’ve successfully completed over 40 PCB projects in the last 12 months, all using 0.3 mm pitch micro CSPs and micro BGAs.

Many PCB design and layout engineers largely rely on traditional 0.5 mm pitch design guidelines and layout rules to develop new 0.3 mm pitch devices-based designs. For example, the older design guidelines allow PCB design and layout engineers to design a solder-ball-joint pad with the diameter of 20 percent less than the diameter of a BGA/CSP solder-ball.

But the issues associated with using earlier generation design rules and guidelines for 0.3 mm pitch devices-based designs can be far ranging. Suffice it to say that when PCB designers do this for 0.3 mm pitch micro CSPs, for example, solder paste deposition on the balls is not adequate, thereby creating opens and voids on assembly joints.