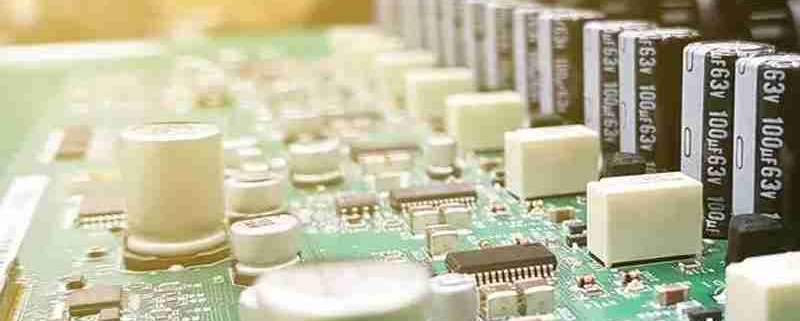

Basic process to assembly PCB board with components.

As a China original PCBA manufacturer ,we do PCBA board according to Bom list & Gerber files via SMT machines & DIP assembly.

Below is the basic process to assembly PCB board with components.

1.Confirm the necessary files and order details.

2.Order and receive the SMT paste stencil if necessary.

3.Program our machines from the BOM and Centroid file, before the materials arrive.

4.Materials are received in. Materials are audited before your job is run.

5.If all materials are in before noon, the assembly clock starts that day. If after noon, the clock starts the next day.

6.A SMT stencil and stencil printer are used to mechanically apply the paste.

7.An automatic pick and place machine place the SMT components.

8.A SMT reflow oven is used to reflow the solder onto the SMT components.

9.BGA components are X-rayed to verify placement accuracy and to detect any solder bridges.

10.Thru-hole parts are inserted by hand. They may also be wave soldered depending on the board layout.

11.A 100% final quality check is performed.

12.The finished PC board assemblies are shipped back to you.