BGA’s ability in design & assembly

Since the solder paste layer is much thinner, we get the same advantages as the BGA package, but even more so; thermal resistance is even smaller, and inductance is even lower. For modern power-dense point of load modules, which can carry very high currents , thermal efficiency is more important than ever before; BGA’s thermal advantages can make a real difference. The technology’s lower mounting height, even though we are only talking about a fraction of a millimetre, can help lower the profile of the board so as not to obstruct air flow around the system.

BGA also offers designers the ability to optimise the connections for either shock endurance or long-term reliability by choosing between two solder mask profiles. SMD (solder mask defined) means the solder mask hole is smaller , so solder doesn’t cover the entire pad. This is used in applications like portable devices where the risk of impact forces is high, such as in portable devices which may be dropped. the solder overlaps slightly. This provides greater long-term reliability as it reduces the risk of solder fatigue, and it’s commonly used in industrial and avionics applications. These optimisations cannot be made using standard technology as the solder balls are a standard size.

C-Alley could provide one-stop pcb assembly service,Include:

– Contract PCB Manufacturing

– Engineering Services

– PCB Design & Assembly

– Component Procurement & Material Management

– Product Design

– Fast Track Prototyping

– Cable and Wire Assemblies

– Plastics and Molds

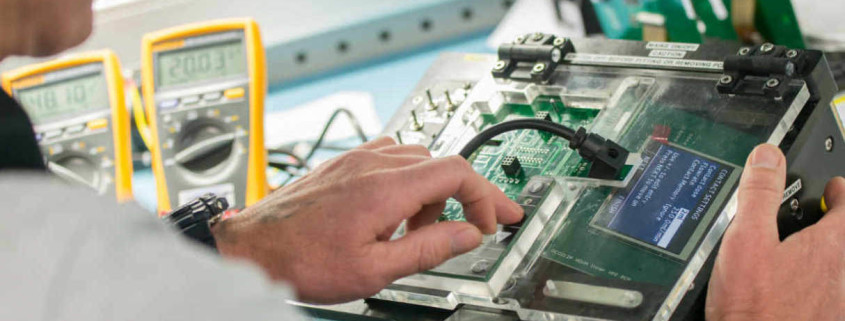

– Function Testing Service