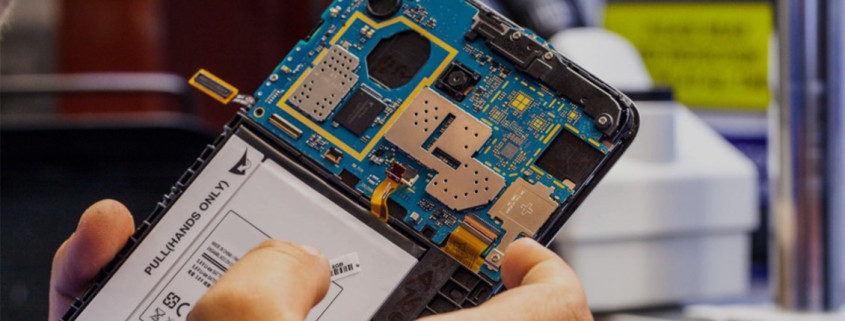

C-Alley – China PCB Assembler with Advanced Equipments

C-Alley Co., Ltd is a leading high-end China PCB Assembler specializing in the production of high-quality PCBs and electronic assemblies. And the factory located in Shenzhen for more than 15 years.

We pride ourselves on offering advanced technology, state-of-the-art equipment, and stringent quality control measures.

Most of our customers are worked with us for more than 10 years in PCB FAB, Circuits Assembly, HDI, and PRINTED CIRCUIT DESIGN, some of them are worked with us for more than 5 years, we have a good reputation in Germany, and Japan, Russia, Ukraine and so on.

Here are some key aspects of the C-Alley PCB Assembler:

- Advanced PCBA Manufacturing and Testing Facilities: Equipped with cutting-edge automated machinery, including advanced printing, surface mounting, and soldering equipment, we ensure efficient production processes and superior product quality.

- Premium Quality Materials: We utilize top-notch materials such as high-precision glass fiber cloth and highly conductive copper foil to guarantee excellent performance and reliability of our PCBs.

- Advanced Production Techniques: Our expertise lies in utilizing advanced production techniques such as multi-layer boards, high-density interconnect (HDI), and blind/buried vias to meet the demands of complex circuitry while enhancing functionality and reliability.

- Rigorous Quality Management System: We have implemented a comprehensive quality management system that covers every aspect from material procurement to production processes. This ensures that our products meet customer requirements and comply with international standards.

- Strong Supply Capability: Equipped with 12 SMT lines, each line has AOI and QC, and each project has an engineer checking who will ensure a 99.7% workable rate for mass production.

In addition to our state-of-the-art manufacturing capabilities, we have invested in a range of high-end production testing equipment to ensure the quality and reliability of our PCBA products. These include:

Automated Optical Inspection (AOI) Systems:

Utilized to detect defects such as solder joint shorts, open solder connections, and missing components during the assembly process.

X-ray Inspection Equipment:

Used to inspect internal solder joints and identify defects like cold solder joints, voids, and poor solder connections, providing comprehensive inspection results.

In-Circuit Testing (ICT) Systems:

Employed to test the correctness and performance of electronic components, including resistance, capacitance, and inductance, to ensure compliance with design specifications.

High-Speed Flying Probe Testing Equipment:

Used to test connectivity, signal transmission rates, and other parameters on the PCB, guaranteeing adherence to design requirements.

At our PCBA company, we strive to deliver high-quality products that meet the diverse needs of our customers. With our advanced manufacturing facilities, stringent quality control measures, and cutting-edge testing equipment, we are confident in our ability to provide reliable and innovative solutions for your PCB assembly requirements.

In 2022, China PCB Assembler was the dominating supplier of printed circuit assemblies to the US, making up 58% of US imports.