It’s not ok to place components at the edge of a PCB (< 5mm)

The PCB traverses stations on the assembly line on a conveyor belt. This conveyor belt, which is located along (almost) the entire production line, is composed of two parallel tracks. These tracks comprise a small depression that enables the PCB’s stability on the conveyor belt. The projection of the depression’s area on the PCB is unreachable by the placement machine head. Therefore, no components should be placed in that area. Placing components at the edge of a PCB (< 5mm) may make it difficult or even prevent the machine’s head from placing these components accurately on the PCB. In light of this, it is necessary to verify a “sterile” component-free area is defined at a distance of 5mm from the PCB edge. In exceptional cases, it will be possible to define even smaller distances, but solely upon coordination with the assembler.

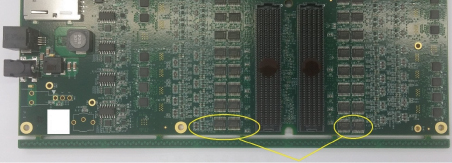

In the event the PCB is very dense and the entire board area must be used for components, it is possible to take advantage of the margins used as a support basis for the PCB during production assembly. In this manner, it will be possible to place components even closer to the edge, up to a distance of 1 to 1.5mm. In this case, margins are added to the PCB, wide enough to constitute the PCB’s point of application on the tracks of the assembly machine. These margins are removed after assembly to resume the PCB’s “generic” size (FIGURE 3).