High-Precision PCB Assembly, Providing One-Stop Electronic Component Service

In today’s world, electronic devices and circuits have become an integral part of daily life. The gadgets we use daily like phones, computers, television, and cars have all become smarter and more complex, thanks to the advancement of PCB assembly technology. PCB, or Printed Circuit Board, is a critical component of these electronic devices that connect all the electronic components, ensuring their proper functioning. The high-precision PCB assembly service not only offers a seamless solution to the electronic industry but also helps to improve the reliability, accuracy, and durability of electronic devices.

With the rise of a diverse range of electronic devices, select PCB assembly providers have specialized in offering one-stop electronic component services to their customers. This service offers a comprehensive solution to the manufacture of complex electronic devices, including the customer’s product idea to the finished product. These one-stop services include prototyping, design, fabrication of the printed circuit board, component procurement, surface mount technology (SMT), manual through-hole assembly technique, functional testing, and final assembly. This approach is convenient for their customers because it eliminates the need to interact with multiple service providers, resulting in product quality control from start to finish while saving time and costs.

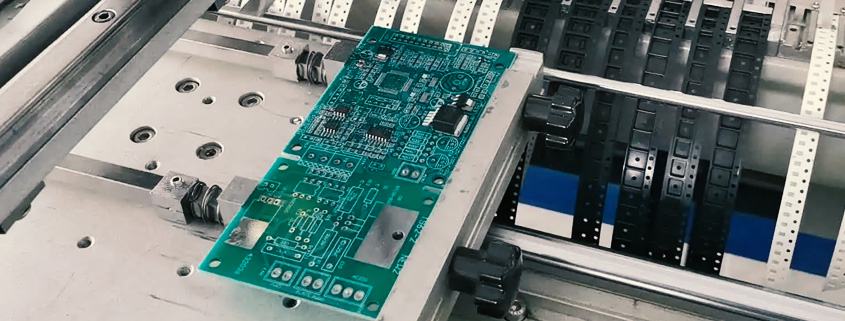

High-precision PCB assembly often entails the latest PCB assembly technologies, including surface-mount technology (SMT), which involves the attachment of electronic components on the surface of PCBs. This technique has several benefits. First, it enhances the circuit board’s reliability by reducing the connection wires. Second, SMT enables the PCB to have more components assembled into it, increasing the functionality and performance of the device. Third, SMT consumes less space, making it suitable for the fabrication of smaller PCBs.

On the other hand, the manual through-hole assembly technique helps to connect electronic components on the opposite side of the PCB surface. This technique is suitable for electronic devices requiring a stable mechanical and chemical bond between the components and the PCB, compared to the less stable solder joints obtained from SMT.

The one-stop PCB assembly service providers pride themselves on their quality control measures to ensure that all components and PCBs assembled conform to the customer’s specifications. They have quality control procedures that ensure that individual components meet set standards, the assembly process flows systematically according to a set procedure, and inspection methods are undertaken after assembly to verify the integrity of the electronic devices in the final assembly stage.

In conclusion, the high-precision PCB assembly service provides a one-stop electronic component service that offers a comprehensive solution to customers’ electronic component fabrication needs. These services not only provide quality assurance to electronic devices but also save time and costs incurred through interacting with multiple service providers. PCB assembly and its relevant technologies continue to evolve, and it’s essential for service providers to keep up-to-date with the changing trends. This will give them a competitive edge in the market while offering superior service to their clients.