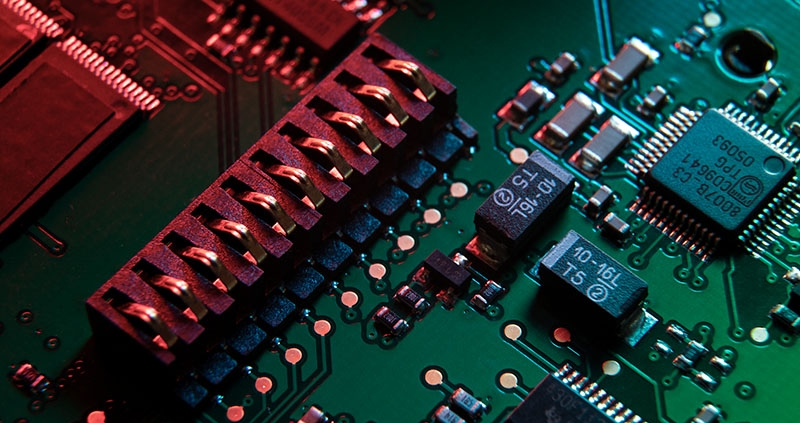

Quick Turn SMT prototyping

C-Alley is an Expert in quick turn SMT production, with a solid reputation of on-time delivery and competitive cost, we build and manufacture over 500 prototypes a year, with capability designed to deliver with quality, speed, and flexibility.

The biggest advantages are in SMT equipment: 8 automatic SMT equipment lines, Hitachi screen printer, Fuji NXT-ii SMT machines, Fuji XPF-L module SMT machines, X-Ray machine, BGA inspection.

Why is quick turn SMT used in industry? SMT has several important benefits over through-hole technology.

– Faster for automatic machines to place

– Has a smaller physical size for the same electrical function

– Less parasitic (unwanted) effects

– Cost of part is cheaper

1) Fast delivery service.

2) Complex SMT capability.

3) Production quality standard prototypes.

4) Batch sizes from 1 off upwards.

5) 9 lines with SMT placement machines.

6) World-class solder jet printing technology.

7) PoP, BGA, leadless, 01005, 0201, 0402, QFN, DFN, etc.

8) Hard-to-mount SMT parts, connectors, leadless, cavity & small process window.

9) 100% AOI inspection as standard.

10) Skilled IPC accredited technicians to IPC standards.

11) IPC class 2, 3, or J-STD.

12) Ultrasonic and aqueous cleaning.