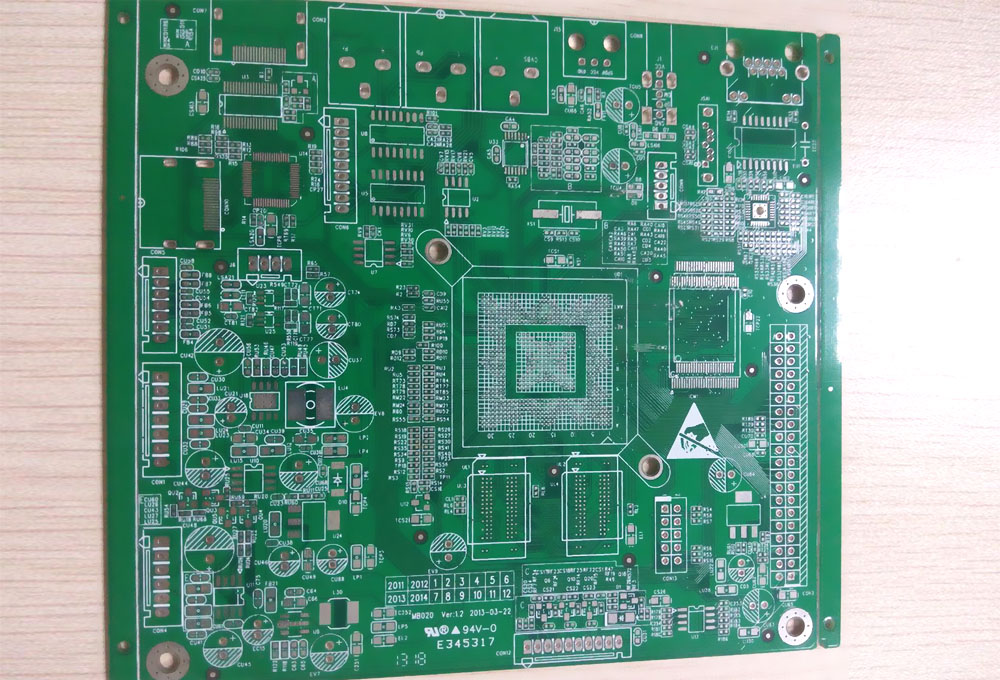

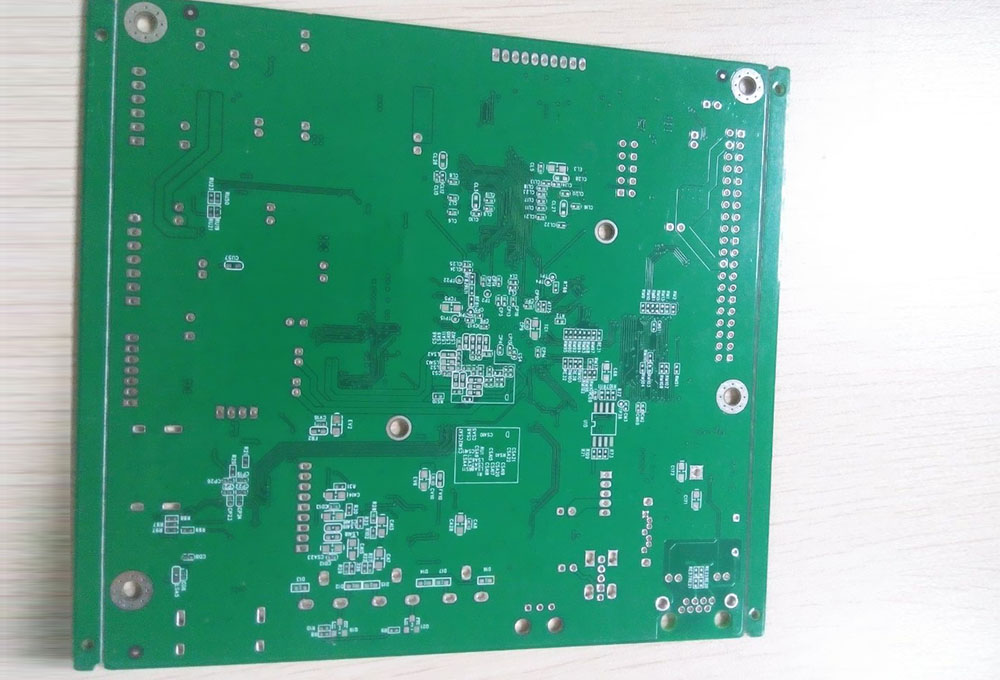

PCB Prototype

PCB Prototyping

At C-ALLEY we are now able to offer our customers any kind of prototype circuit boards they require. Whether our customers need single or double-sided FR4 boards or very high technology blind and buried via boards, boards made with unique materials, metal core boards, heavy copper boards, rigid-flex PCB and flex PCB, they will be able to get them from us.

Prototype PCB Fabrication

Standard Prototyping – for small quantity 1 or 2 layer PCBs. Includes: 5 day turnaround, top and bottom silkscreen and e-testing, standard.

Panel Prototyping – for multiples of 1 and 2 layer PCB designs nested on panels. Includes: 5 day turnaround, top and bottom silkscreen and e-testing, standard for 40 sq in panels, plus the option to expedite to a 3 day turnaround.

4-Layer Prototyping – for small quantity, 4 layer+ PCBs. for single piece 4 layer+ PCB. Includes: Top and bottom silkscreen, e-testing and 10 day turnaround standard, with the option to expedite to 6-10 days .

Call us at C-ALLEY or get an instant PCB quote with our online quoting system.

C-Alley specialized in manufacturing high-quality prototypes with quick turnaround times and competitive pricing. We provide a streamlined process from design to delivery, ensuring that customers receive their PCB prototypes promptly.

Here is an overview of the PCB prototype process with C-Alley:

Design: Customers can create their PCB design using their preferred PCB design software or utilize C-Alley’s design tools and resources.

File Preparation: Once the PCB design is complete, customers need to prepare their design files for submission. C-Alley accepts various file formats, including Gerber files, Excellon drill files, and BOM (Bill of Materials) files.

Quotation: C-Alley provides an instant quotation based on the specified requirements.

Ordering and Payment: Customers can review the quotation and proceed to place order and make the payment online using the available payment options.

Fabrication: After the order confirmation and payment, C-Alley begins the fabrication process. They utilize advanced PCB manufacturing technologies and high-quality materials to ensure the accuracy and reliability of the prototypes.

Quality Control: Throughout the manufacturing process, C-Alley employs rigorous quality control measures to ensure that the PCB prototypes meet the required standards. This includes inspections, tests, and adherence to design specifications.

Shipping and Delivery: Once the PCB prototypes pass the quality control checks, they are carefully packaged and shipped to the customer’s specified address.