PCB Fabrication

C-ALLEY currently utilizes Automatic Production lines for manufacturing PCB’s (PCB Fab) Quickly. In addition to C-ALLEY’s Engineering capabilities, our experienced engineers and helpful support staff will ensure that you get PCB fabrication exactly to your specifications.

PCB fabrication is the process of manufacturing printed circuit boards that are used to connect electronic components and provide electrical pathways for the flow of signals and power. PCBs are essential parts in a wide range of electronic devices, from smartphones and computers to automotive systems and industrial equipment.

The PCB fabrication process involves several steps:

Design -> Layer Stackup -> Copper Cladding -> Photolithography -> Etching -> Drilling -> Plating -> Solder Mask and Silkscreen -> Testing

After the fabrication process, the manufactured PCBs are ready for assembly, where electronic components are mounted onto the board, soldered, and interconnected. This assembly process completes the PCB manufacturing cycle, and the finished product can be integrated into electronic devices.

PCB fab requires specialized equipment, expertise, and adherence to quality control measures to ensure reliable and high-quality PCBs.

Don’t miss our printed circuit board solutions in Case Studies, offering a diversity of C-ALLEY’ PCBs, programming and integration.

For detail you can check here: PCB Production Capability (or click the button as below)

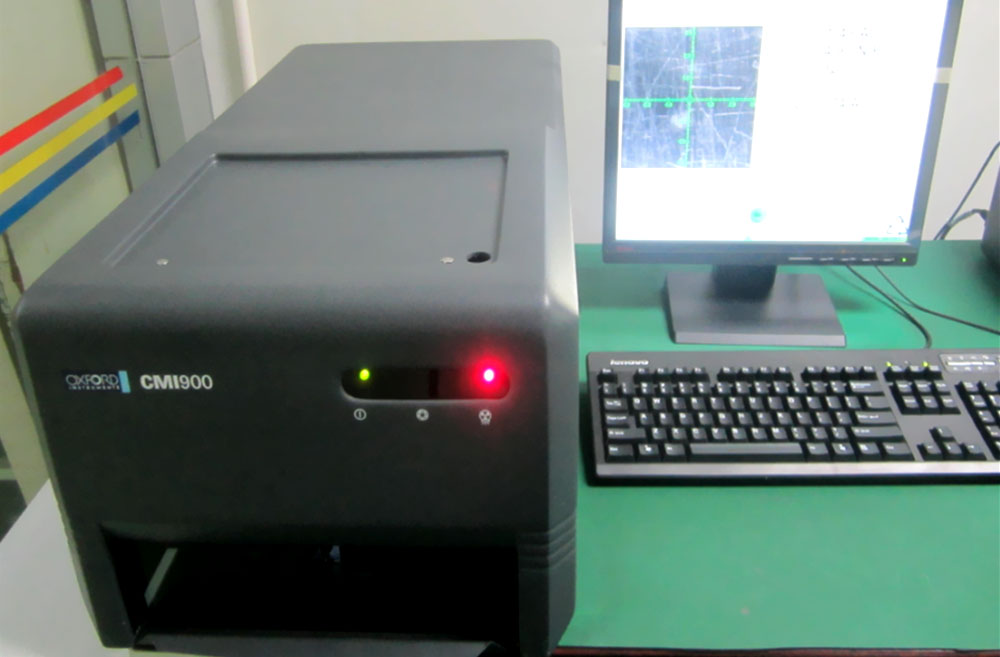

Impedance Test

Insulation Resistance Instrument

Peeling Strength Tester

Ion Contamination Tester

Automatic Optical Inspection Machine (AOI)

X-ray Metal Thickness Test

Two-dimensional Measurement Machine

LF-HASL

Pattern Plating Line

Vacuum Press

PTH Equipment

CNC Drilling Machines

S & M Pre-treatment

Inner Layer Automatic Exposure Machine

Quote Now

Please share your detailed requirements and projects with us, we will try our best to offer satisfying solution.