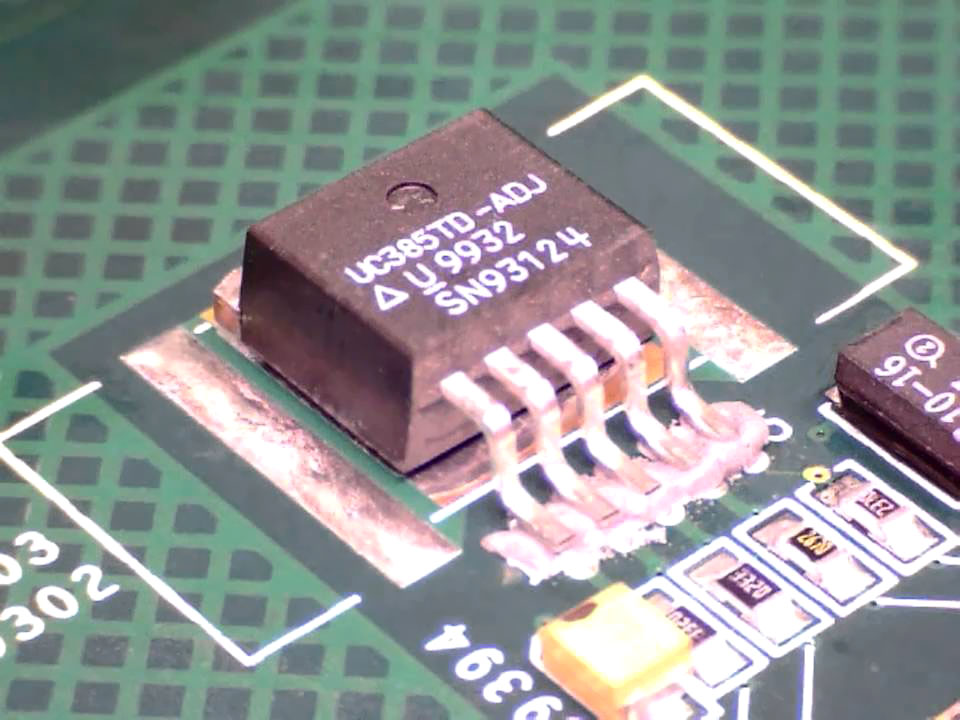

PCBA Copy and Redesign

C-Alley’s common technology of PCB clone is comping the same functions as original printed circuit boards, and redesigning PCB boards according to the client’s requirements to win the market.

PCB Clone process :

Step 1, Two pieces of sample boards are needed for cloning, strip all the components off the board, printing a bill of materials (BOM) by machines automatically analysis.

Step 2, Scan the circuit board to make PCB File or Gerber file.

Step 3, Start to make a new sample for your testing, once getting PCB File and BOM List.

There are four important reasons for choosing us to resign or copy PCB boards.

1. Current technology and components

Making a direct copy of an existing circuit board limits you to using the technologies available when it was first designed – which means you’re stuck using older systems and obsolete, hard-to-find components.

Reverse engineering the circuit board retains 100% functionality while reducing costs by using readily available, cheaper, easier-to-handle parts and processes.

2. Original plans in a universal format

Making a direct copy of a circuit board may not be possible, particularly with multi-layered PCBs. Some people X-ray PCBs or actually abrade the board, layer-by-layer, to make photocopies. These approaches, however, introduce errors that can impair functionality.

Reverse engineering the PCB gives you a first-generation set of plans no matter how complex the circuit board is.

3.No intellectual property conflicts

There may be copyright issues to circuit board cloning that could expose your organization to liability if you don’t own all the intellectual property rights.

In contrast, according to U.S. copyright law, the result of reverse engineering is not a copy. Although the new PCB is functionally identical to the old one, there are enough differences, including current trace routing and updated component specifications, to make it an original piece of work.

4. The ability to move forward

Unlike simply copying the circuit board, reverse engineering reveals how the circuit board does what it does. You get all-new manufacturing files, including schematics, Gerber files, and drill files for each layer. That enables you or your design team to improve the product or add capabilities going forward.

We’ve done numerous projects in which an existing circuit board was simultaneously reverse-engineered and upgraded. We can even build pre-production prototypes for testing.