High Frequency PCB

The increasing complexity of electronic components and switches continually requires faster signal flow rates, and thus higher transmission frequencies. Because of short pulse rise times in electronic components, it has also become necessary for high frequency PCB technology to view conductor widths as an electronic component.

C-Alley High frequency PCB customization services will bring customers more choice and flexibility, providing a reliable solution for the development of high frequency electronic equipment in various industries. Whether you are working in wireless communications, aerospace, medical devices or other fields, C-Alley will be your ideal partner.

High frequency PCB has a wide range of applications in wireless communication, radar system, satellite communication and other fields, and has high requirements for signal transmission and performance stability.

High Frequency Printed Circuit Board Manufacturing from C-Alley

As a professional supplier of electronic manufacturing solutions, C-Alley enjoys a reputation in the industry for its advanced technology and high-quality products. Their high frequency PCB services offer a variety of options that can be customized to meet the specific needs of the customer. Whether single-layer, double-layer or multi-layer PCBS, C-Alley provides professional design and manufacturing to ensure superior performance of high frequency circuits.

C-Alley focuses on technological innovation and quality control, using advanced processes and rigorous testing processes in the manufacturing process of high-frequency PCB to ensure that every PCB meets the highest standards. Their engineering team consists of experienced professionals who are able to provide a full range of technical support and solutions to ensure that customer needs are met.

Whether it is small-scale production or mass customization, C-Alley is able to respond quickly to customer needs and provide high quality service. They are committed to building long-term relationships with customers, providing comprehensive pre-sales consultation and after-sales support to ensure customer satisfaction and project success.

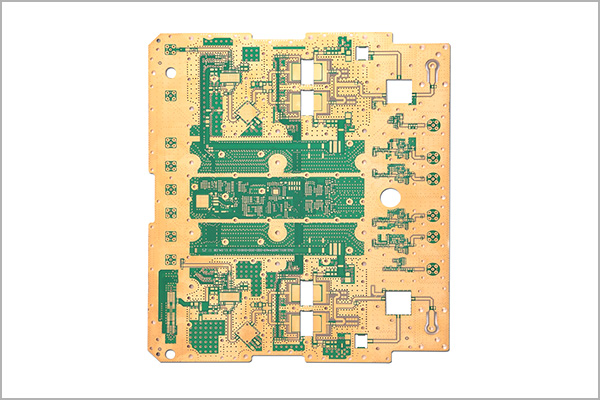

Layers:4L

Thickness: 1.6mm

Min Hole Size: 0.15mm

Min Line Width: 0.1mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance:+/-0.05mm

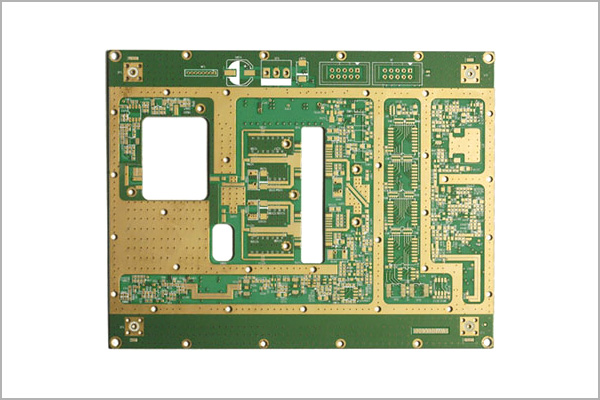

Layers: 4L

Thickness: 1.6mm

Min Hole Size: 0.15mm

Min Line Width: 0.15mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance:+/-0.05mm

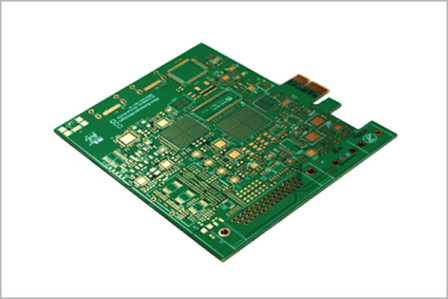

Layers: 6L

Thickness: 1.2mm

Max Length: 1265mm

Min Line Width: 0.1mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance:+/-0.05mm

Layers: 6L

Thickness: 1.6mm

Min Hole Size: 0.15mm

Min Line Width: 0.1mm

Copper Thickness: 1oz

Surface Finishing: ENIG

Molding Tolerance: +/-0.05mm

High Frequency Production Capability

| Item | Standard | Advanced |

| Max.Layer count | 30 | 32 |

| Min. Drill Size | 0.15mm | 0.15mm |

| Min. Laser Drill Size | 0.10mm | 0.075mm |

| Min.BGA Pitch | 0.40mm | 0.20mm |

| Impedance Control Tolerance | ± 8% | ± 5% |

| Max.Cu Thickness | 5oz | 12oz |