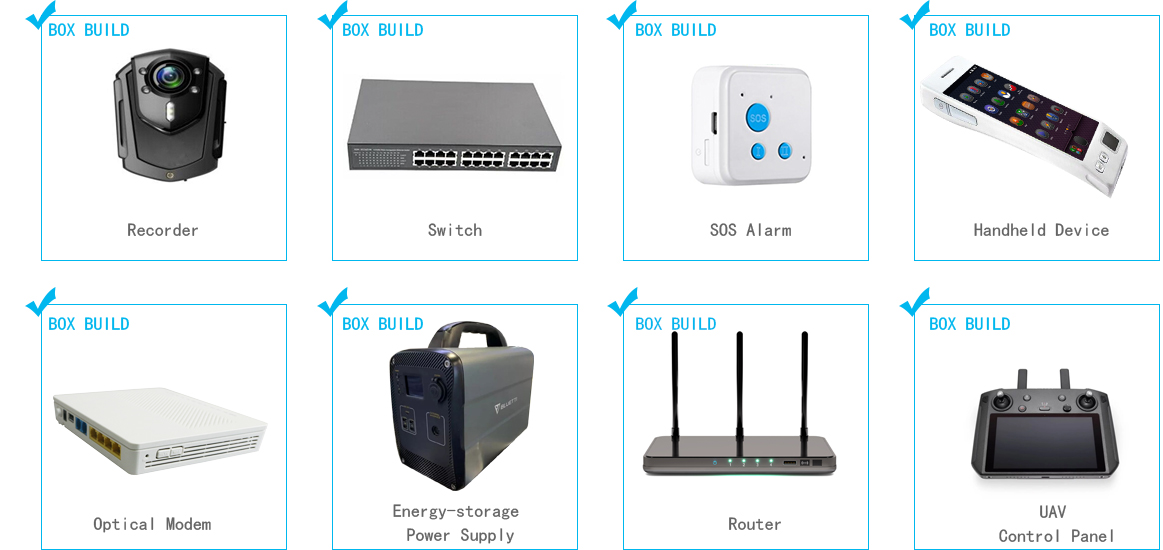

Box Build Assembly

| PCB Assembly | Metal Assembly | Enclosure Assembly | Case/Housing Assembly |

| Cable Assembly | System-Level Assembly | Functional&Reliability Testing |

C-Alley provide one-stop Box Build assembly which include Metal/Enclosure Assembly,Case Assembly, System-level Assembly, Functional&Reliability Testing or other testings in need. Daily capacity can reach 1K sets.

We can provide full turnkey solutions for your Small / Light through Large / Heavy Box Build requirements. As a result of our significant experience, we are able to provide competitive and knowledgeable labor and manufacturing analysis to streamline our customer’s total Cost of Ownership for their product lines.

Box build assembly services offer several benefits for users. This assembly can include items such as pneumatic devices and further electronics to the printed circuit boards.

Reduction in production costs: Electronic manufacturing services can pay for fewer wires, connectors, and tie wraps that you might purchase in small lots. A good build assembly service ensures that its employees understand the testing and installation of different build boxes.

Experience helps to improve work quality and productivity. One of the benefits you enjoy when you employ the services of EMS is that they can switch between models easily.

Quality: Good electronic product assembly services ensure they do the right job. They do their job with quality in mind. Working with a box build assembly service that ensures good systems integration by carrying out some tests is important for higher assembly processes.

Supply chain simplification: This is what complete electronic product assembly services do. These services provide expertise. They can tell you what to do about streamlining your design. They will reduce the complexity of your overall supply chain since they are responsible for creating or purchasing cables, circuit boards, and chassis.