PCB Assembly Plant Equipment List

PCB Assembly Plant Equipments: 8 automatic SMT equipment lines, Hitach screen printer, Fuji NXT-ii SMT machines, Fuji XPF-L module SMT machines, X-Ray machine, BGA inspection.

C-Alley Equipment Lists

FUJI XPF-L Modules SMT Machines

FUJI NXT-II Modules SMT Machines

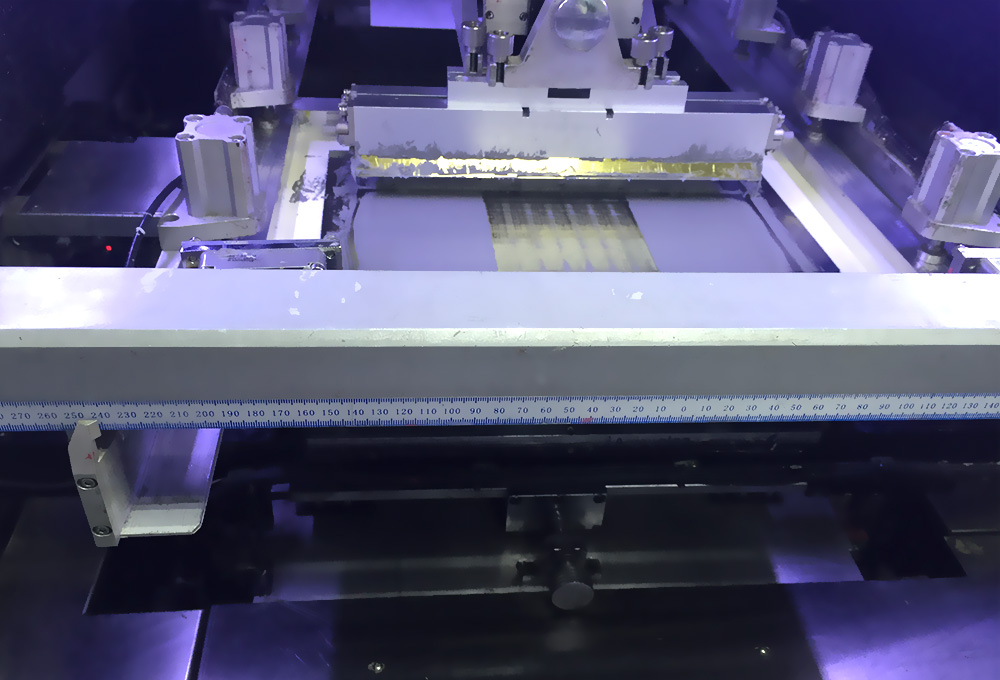

HITACHI Screen Printer

Reflow Oven

SMT Lines

SMT Lines

For IC & BGA Storage

PCB Baking Oven

Solder Paste Storage

BGA Rework Machine

X-Ray

AOI

3D SPI (Soder paste testing inspection)

Wave Sodering

• High precision, speed and stability

• High identification position system

Applicable to the production

• PCB Size(LxW)mm

Min 50×50~Max 330×250

PCB Thickness:0.4 ~3.0mm

Stencil size(LxW)mm: 650×550

FUJI XPF-L Mounting

FUJI NXT II Mounting

High precision, speed and stability

High recognized position system

Daily production capacity can reach 1.05 million points

Be applicable to the production:

PCB Size(LxW)mm

Min 48×48~Max 534×510

PCB Thickness:0.4 ~3.0mm

Specifications for SMT components:

QFP, TQFP, BGA, QFN PLCC, SOT, SOIC

(Pitch 0.3mm)

1005、0201、0603、0402

3216、 2125、 1608、

Please note that this is not an exhaustive list, and our PCBA plant may have additional specialized equipment and tools to cater to specific project requirements. C-Alley is committed to maintaining state-of-the-art equipment to ensure efficient and high-quality PCB assembly processes.