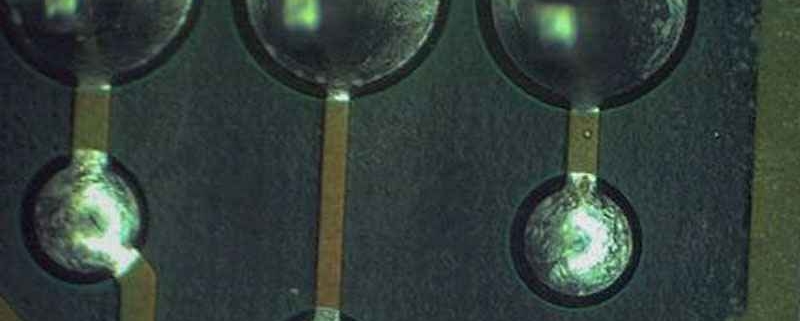

Solder balls and solder beading problems

Solder balls and solder beading have been a process issue for many years and they may not cause product failure or quality problems but they are not desirable. Solder balls are caused by a variety of factors in different processes and should be resolved to eliminate a poorly defined process or a process and materials which are out of control .

Solder beading is a special phenomenon of solder balling when using solder paste in certain SMT applications. In brief, solder beads are large solder balls near components with very low stand-off . With more attention being drawn to no-clean paste applications due to CFC concerns, a better understanding of this event becomes indispensable.

Solder balling can be caused by poor process conditions with gassing from the flux during wave contact or excessive turbulence as the solder flows back into the bath which causes spitting. Solder balls can be ejected from the joint area during soldering due to excessive outgassing of the PCB.

So way you can remedy this by modifying your aperture, and hence your print shape, of the solder paste deposit for those ceramic capacitors.